Noise

Noise is any kind of sound in the audible frequency range - Workplace:

Noise-induced hearing damages are incurable. Contemporaneously, individuals with impaired hearing get into social isolation very easily.

The new Regulation on Noise and Vibration (BGBl. II Nr. 22/2006) has been in force since February 2006 and applies to all workplaces, construction sites, and out-of-town job locations with employees’ exposure to hazard generated by noise or vibration.

Vibrations are mechanical oscillations or concussions being transferred to the human body through direct contact. A distinction is made between hand-arm vibrations and whole-body vibrations.

Guideline imposes standards for businesses concerning the way of dealing with noise and vibration at the workplace. With the regulation, the legislator constituted preventive trigger values for noise harmful to hearing, as well as for vibration hazardous to health. In addition, permissible exposure limits were laid down.

As soon as a trigger value – as stipulated in standards – is reached or exceeded, the employer must contrive measures to alleviate exposure. In addition, the employer has to make appropriate personal protective equipment available to the affected employees. At the latest when reaching the permissible exposure limit specified in standards, the employer is required to implement the planned measures.

Noise

Noise-induced hearing loss is one of the most frequent occupational diseases. The noise situation at workplaces can be improved in different ways:

- Introduction of new, less noisy processes

- Enclosure of machinery

- Noise abatement measures in working areas

Once these measures are exhausted, ear protectors have to be worn when exceeding limit values.

Vibration

Mechanical oscillations and concussions or vibrations respectively, which impact human beings, are referred to as human oscillations. Depending on the vibration-stressed body location, whole-body vibrations or hand-arm vibrations are being distinguished. The stress level depends on amplitude, frequency, the direction of vibration, and type of oscillation (vibration or impact). Also of major relevance is the duration of the vibration load.

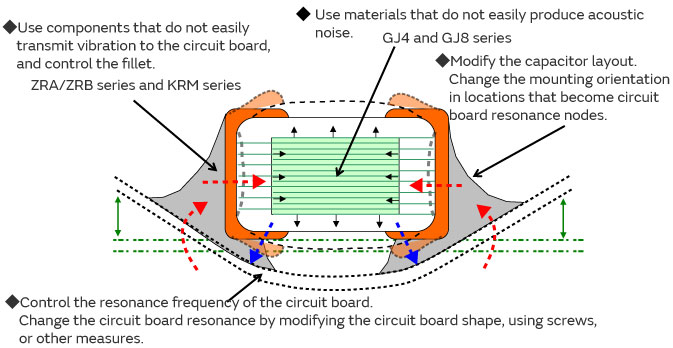

The periodic oscillation of substances and bodies is called vibration. Vibrations are an important parameter in machinery, buildings, and vehicles.

Vibrations also have a big impact on people and they are called “human vibrations”. Depending on the frequency of vibration and the exposure time first general discomfort and later various symptoms including pain in the abdomen or chest and back pain or headaches could occur. Years of exposure to vibration could lead to spinal and joint damage. In addition, vibration-induced circulatory disturbances occur, especially in the hands.

Every building experiences a certain amount of shock and/or vibration-whether caused by people or machinery. Vibration is a mechanical phenomenon in which periodic motion is generated by a force around an equilibrium point. The possible effects of these vibrations can vary from insignificant to disastrous, depending on the intensity and duration of the shock as well as the construction of the concerned structure or equipment.

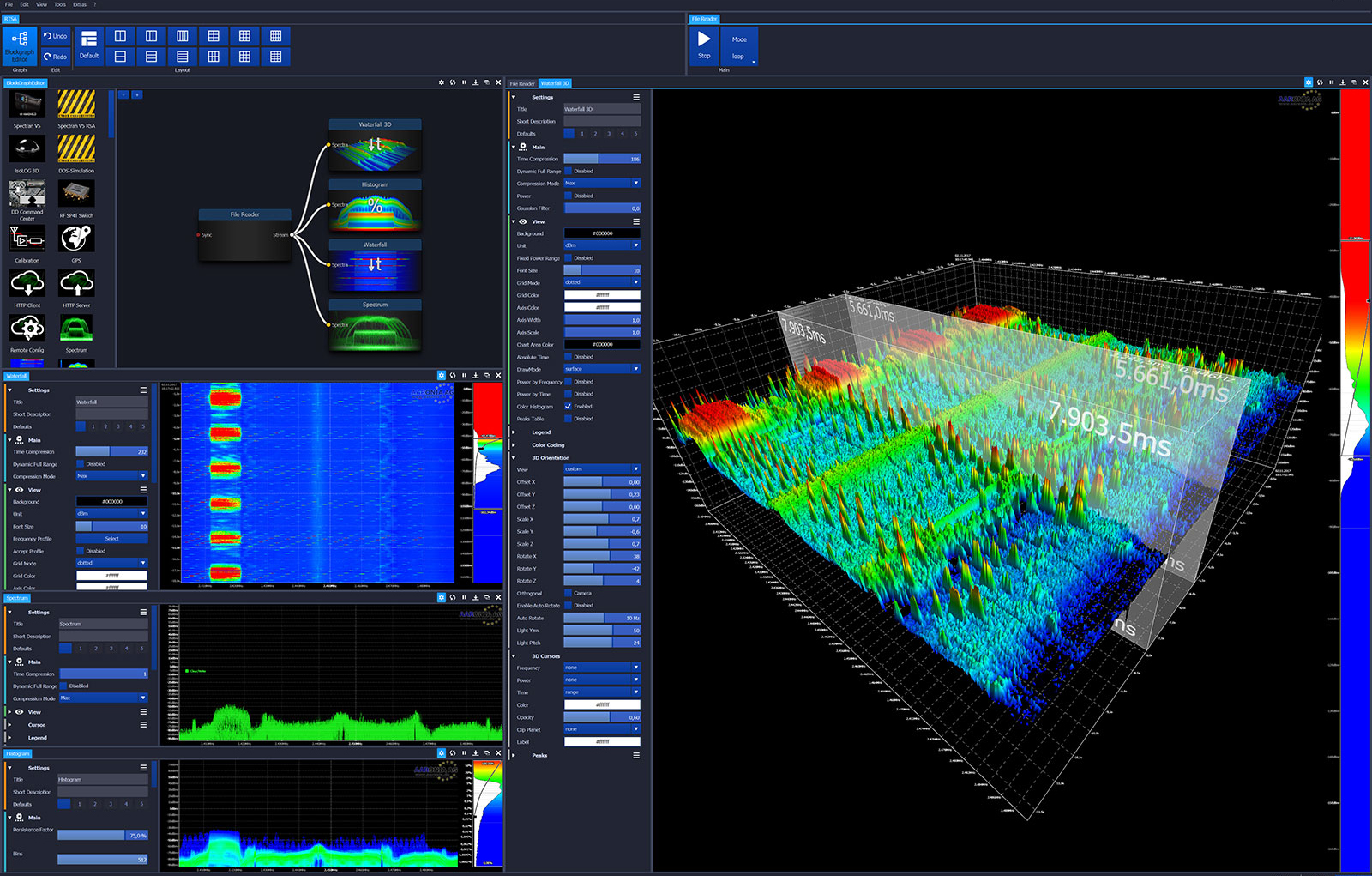

Rotating machinery, such as blowers, motors, and components in computers, also tend to vibrate and can cause significant damage to the pieces around it. These components may transmit vibration and noise to the surrounding structure, having a negative impact on the machine’s production or reliability while also affecting humans working with these machines.

As compared to stationary installations, mobile machines like vehicles and boats experience greater amounts of shock and vibration. Not only are there parts within these mobile machines that create shaking or vibration, but there are also outside forces at work (like irregular roads and air turbulence) that need to be mitigated.

What is transmissibility?

Noise Prediction Calculation environmental

The acoustics benefits from the rapid development of science and software technology. Especially in recent years, the programs for the calculation, presentation, and prognosis assessment of noise exposure in outdoor areas developed rapidly. This prediction programs tell us what noise emissions we have to expect from an industrial plant, a supermarket with a parking lot, a road, or a railway.

Typical applications are:

- Calculation and assessment of industrial and commercial noise

- Calculation and prediction of traffic noise

- Calculation and assessment of aircraft noise

- Generating comprehensive noise maps

The calculations are mainly used in the planning and approval phase of installations, industrial plants, roads, or railways. But also for redevelopment concepts or planning expansions, these calculations are indispensable tools.

Furthermore, large-and small-scale optimization can be performed with these tools, CadnaA is the leading software for calculation, presentation, assessment, and prediction of environmental noise.

We strive to assist our customers with knowledgeable support.

Industrial and Commercial Noise

Noise generated by industrial and commercial premises can impact on residential and other noise-sensitive receptors.

Noise generated from existing industrial and commercial premises can be measured and evaluated in order to determine whether a problem exists. If noise control is required, we can undertake a detailed analysis to identify the sources that require treatment and can assess potential options, including undertaking a cost- benefit analysis. Where a new industry or commerce is to be introduced into an area,an environmental

impact assessment is generally required as part of the planning process and this will often include a requirement to assess the noise impact. Certain processes will also require a permit under the Integrated Pollution Prevention and Control (IPPC) Regulations. Through our network of associate consultants, we can provide advice and

assessment for practically all environmental issues.

Baseline noise levels are generally established by monitoring, and this could be a combination of attended and unattended noise surveys. Noise modelling can be used to calculate noise levels generated by the new industry and the noise impact can be determined. The noise model can then be used to assess the efficacy of various noise control options.

Industrial noise also affects personnel working on the premises. Employee noise exposure can be assessed for anything from an individual employee up to the entire workforce.

Transportation Noise

Transportation is undoubtedly the noise source that affects more people in the world than any other and, as the number of journeys taken continues to rise, transportation noise and the vibration are set to be a significant issue long into the future. Roads, railways and aircraft movements can all generate significant impacts.

We use state-of-the-art noise modelling software capable of modelling even the most complex scenarios and producing high-quality graphical noise mapping.

Proposed scheme layouts can be assessed for their noise impact and comparisons of different scheme options can be assessed. Mitigation options can be assessed at the design stage and cost-benefit analysis can be undertaken.

Existing scenarios can also be modelled and possible mitigation options can be assessed, together with associated cost-benefit analyses. Where noise-sensitive development is to be located near to existing transportation noise sources, mitigation options can be evaluated for incorporation into scheme design.

The very latest noise and vibration measurement instrumentation are available to allow the most appropriate and cost-effective approach to noise and vibration survey work to be adopted. Unattended and attended survey work can be undertaken quickly and effectively.

Petrochemical Plant Noise

Noise generated by Oil and Gas/Petrochemical installations is generally an issue for two reasons:

Noise within the plant/installation itself, which can affect the efficacy of communications, interfere with Public Address and Alarm systems or, at high levels, cause damage to employees’ hearing. Noise at community locations within the surrounding environment.

“Acousticsindia” has been responsible for the noise control design of numerous installations through Pre-FEED, FEED, and EPC, ranging from small expansions of existing facilities to world-scale grass-roots projects.

Our design capabilities include the production of noise models in order to calculate the impact of developments and to identify where noise control is required. Noise control options can be modelled and different scenarios tested to ensure the most cost-effective design. We are used to working closely with the other engineering disciplines to ensure that the noise control design is successfully implemented.

It is common to specify equipment noise limits for individual equipment items and piping. We have experience in negotiating noise limits with Vendors and specifying and witnessing factory acceptance tests.

Noise levels generated by piping can be very significant on oil and gas/petrochemical installations and careful consideration must be paid to these sources during design. Our design capabilities include the assessment of pipe and valve noise and identifying where acoustic pipe insulation should be installed and the appropriate type of insulation.

Noise measurements of installations are often required for a number of reasons, including determining compliance with noise limits. Our measurement capabilities include monitoring both environmental noise levels, in-plant levels, and determining equipment noise levels for individual equipment items. We utilize a broad range of measurement equipment, which allows us to undertake survey work in the most efficient and cost-effective manner.

Employee noise exposure can be assessed for the entire workforce by combining noise levels within areas or modules (either predicted or measured) with a typical employee working patterns. This methodology ensures that noise control can be targeted at the areas that will provide the greatest reduction in exposure to the workforce as a whole.

For existing installations, we can recommend various noise control techniques and undertake a cost-benefit analysis of potential solutions. Where noise control is not practicable, we can determine the extent of restricted areas and assess the efficacy of Personal Hearing Protection.